Dentsply Sirona CEREC

CEREC

The superior digital chairside treatment experience for dentists and patients alike. It enables dental professionals to manufacture dental restorations in their dental office.

After 35 years of continuous optimisation, CEREC gives users the options they need to treat multiple indications with the confidence that comes from outstanding results.

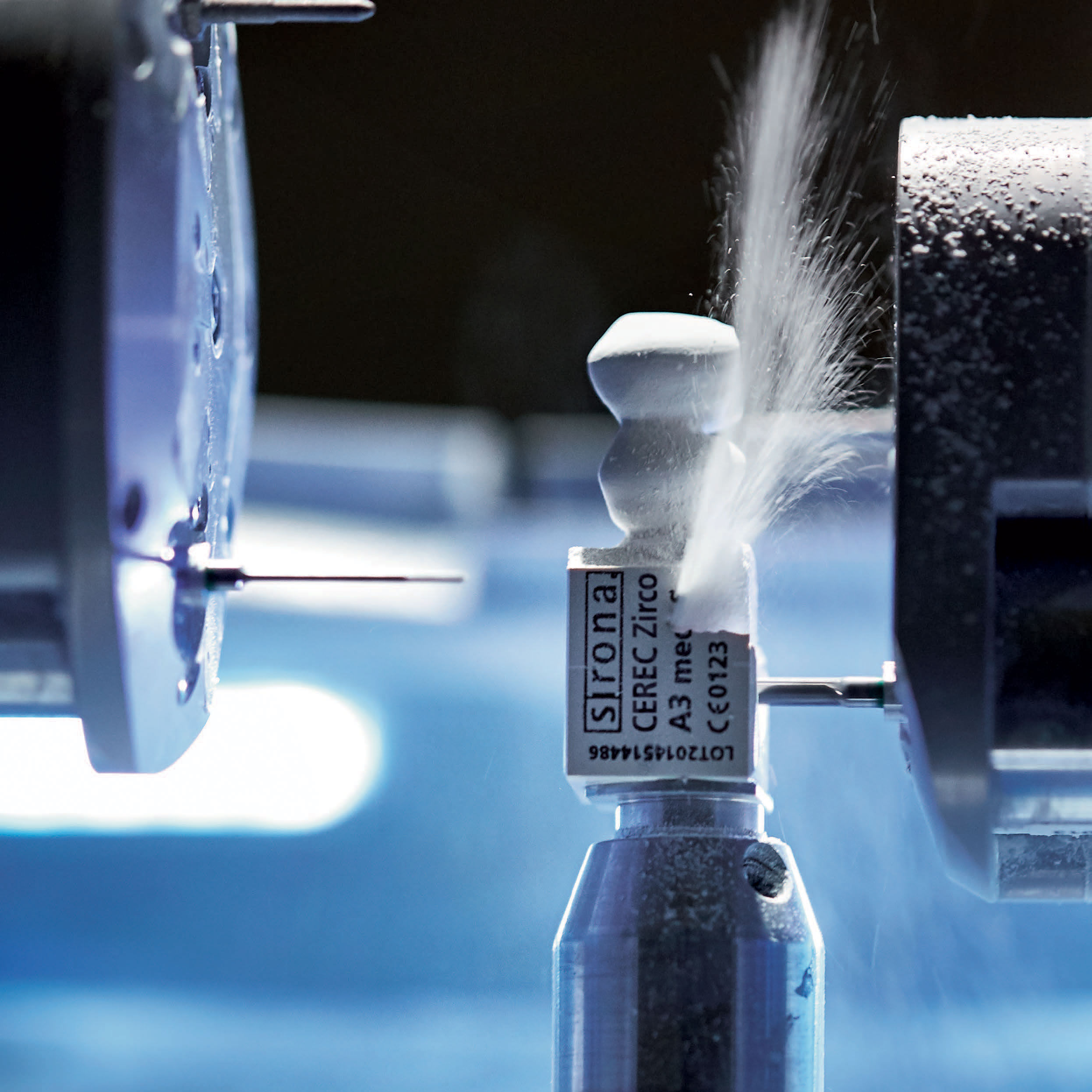

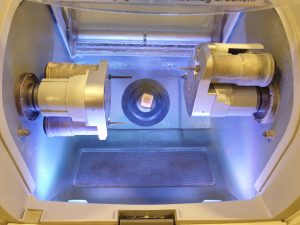

Primemill, MC X, MC XL

Annual Servicing

- All moving parts are cleaned, inspected, and re-lubricated as specified by Dentsply Sirona.

- Electrical components and internal communications are tested.

- Device firmware and software is updated if available.

Fixed cost servicing can also be provided on request.

Call us on 0333 023 0400 to book your service.

Repairs

Regularly maintained devices should provide years of fault-free use, but if the unexpected happens, we can fix it. Our Dentsply Sirona trained engineers have many years of experience working with the CEREC range. Only genuine Dentsply Sirona parts are used. Call us for any consumables and accessories.

Refurbishment

It’s not always necessary to buy new equipment to keep your dental practice working efficiently.

Abacus can collect your hard worked equipment back to our workshop for a complete overhaul. We refurbish it back to nearly new condition, returning it refreshed and ready to go. This prolongs the life of your CEREC milling unit and saves you the cost of buying a new one.

Integration

We can show you how to combine your CBCT & CEREC Data to mill or 3D print extremely accurate surgical guides.

Training

We provide staff training for all Dentsply Sirona CEREC units on regular maintenance to ensure smooth running.

Case study 1

This 4-motor CEREC needed help as a result of practice staff on site being unaware of regular maintenance procedures.

- The water filters had been reused many times and incorrectly fitted allowing unfiltered water into the unit.

- Removing the motor splash covers revealed a layer of biofilm which had formed under the covers, caused by a lack of Dentatec usage.

- Most of the water jets were blocked, milling jobs were failing, and costing the client in broken burs and unusable blocks.

- Abacus managed to save the motors even though the mounting screws were caked in cemented ceramic and seized. We removed both motor assemblies, cleaned the motor shafts, and replaced the air/water o-rings which were dry and cracked.

- The mill chamber was cleaned removing as much ceramic deposit as possible and the plunger pins were cleaned until they operated properly.

- Both motor housings were replaced as heavy ceramic deposits were evident under the spray plates and the state of the internal water channels couldn’t be trusted.

- The unit was treated to a service kit and internal gears were cleaned and re-greased.

- Training was provided to staff covering daily and monthly maintenance, water, filters, use of MC Care Liquid, Dentatec and calibration.

Although refurbishment was quite involved, it cost under £2,500 to complete and saved the client from needing a new mill chamber which would have cost around £15,000.

Case study 2

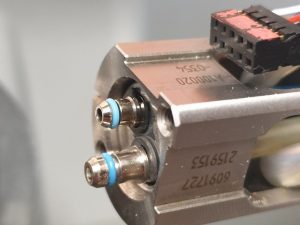

- One of the motors on this 2-motor mill unit was unable to lock into place and the burr couldn’t be removed.

- The plunge pin which the motor uses to lock against had seized in due to an excess of ceramic residue.

- The internal locking mechanism of the motor failed and the motor needed replacing.

- The motor shaft was cleaned and shaft, air, and water o-rings were replaced.

- The plunger pin was replaced and adjusted for correct operation.

Give us a call

0333 023 0400

Whether you’re curious about products, need details about servicing or require advice about design, we’re here to answer your questions.